Understanding the Complexity of Lithium Batteries

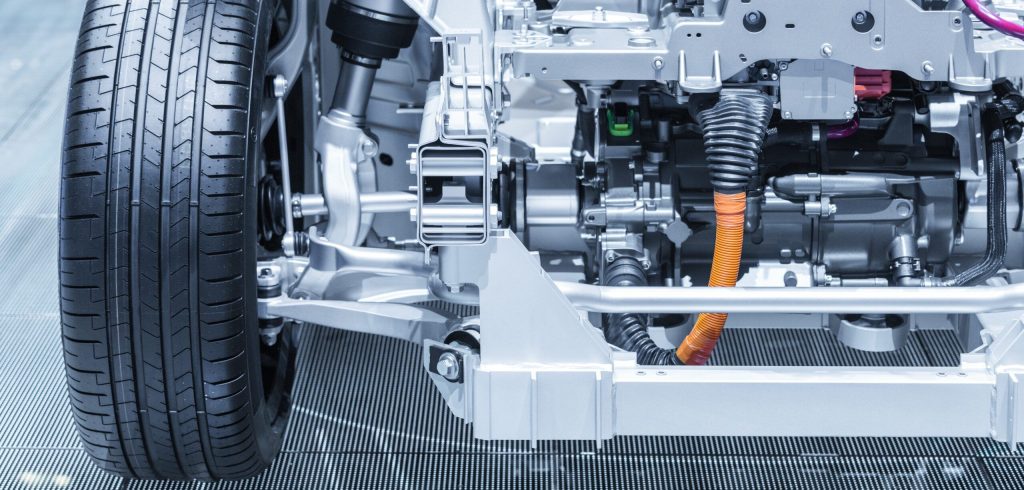

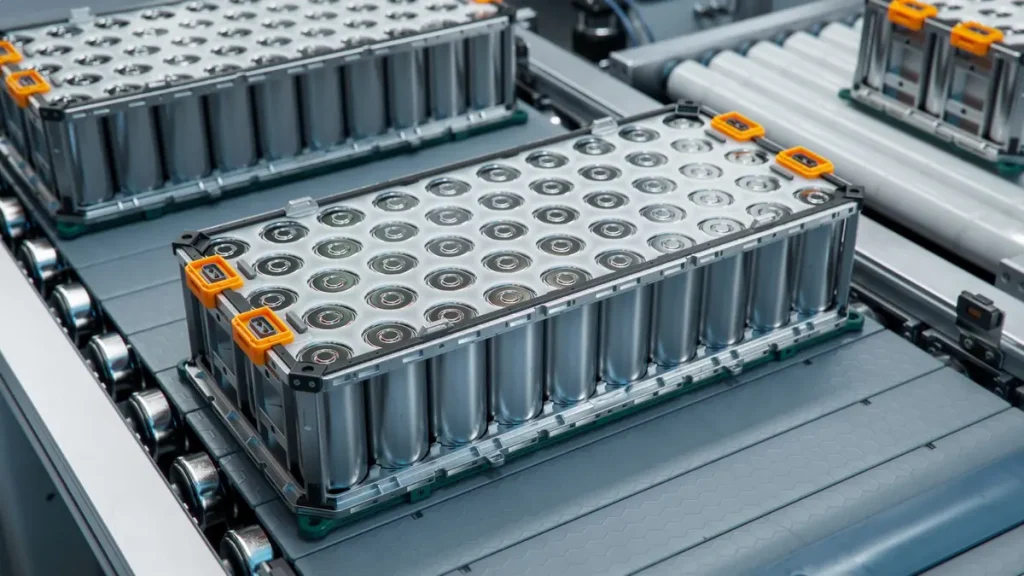

Electric Vehicles (EVs) have revolutionized the automotive industry, offering sustainable and efficient transportation. Central to their functionality is the lithium battery, which provides the necessary power for your EV. Unlike conventional car batteries, lithium batteries are highly complex and sophisticated. This complexity makes them challenging to repair and requires a deep understanding of their chemistry, technology, and safety protocols.

Risks Associated with DIY Battery Repairs

Attempting to perform lithium battery repairs on your own can be fraught with risks. These batteries are sensitive to mishandling and can release hazardous chemicals or catch fire if damaged. Incorrect repairs can lead to short-circuiting, overheating, or even exploding batteries, posing severe dangers to both the vehicle and personal safety. Additionally, DIY repairs often void warranties, which can be costly should professional intervention become necessary later.

Why Professional Expertise is Crucial

When it comes to a lithium battery repair, professional expertise is not just beneficial—it’s essential. Certified technicians have the training and equipment required to safely and effectively repair or replace lithium batteries. They adhere to strict safety standards and use specialized tools to manage the high voltage and energy density of these batteries. Their qualifications ensure that the repairs will restore your battery’s functionality without compromising safety.

The Role of Advanced Diagnostic Equipment

Modern EVs come equipped with intricate battery management systems that monitor the health and performance of lithium batteries. Diagnosing issues within these systems often requires advanced diagnostic equipment. Professional repair facilities have access to such technology, enabling them to accurately pinpoint problems and apply the correct fixes. This precision reduces the risk of further damage and extends the life of your battery.

Long-Term Benefits of Professional Repairs

Investing in professional lithium battery repairs has long-term benefits for both your EV and your peace of mind. Proper repairs can significantly extend the battery’s lifespan, enhancing the overall performance and efficiency of your vehicle. Moreover, professional technicians provide warranties on their work, offering you protection and reassurance should any issues arise post-repair. In the long run, this can save you substantial costs compared to the potential expenses of failed DIY attempts.

Safety First: Always Choose Professional Repairs

The intricate nature and inherent risks associated with lithium battery repairs makes it important to seek professional assistance. By doing so, you ensure the safety, reliability, and longevity of your EV’s power source. Trusting certified technicians to handle repairs protects you from the hazards of DIY attempts and guarantees that your EV remains in optimal condition, ready to deliver the sustainable performance you depend on.